Adamas COU

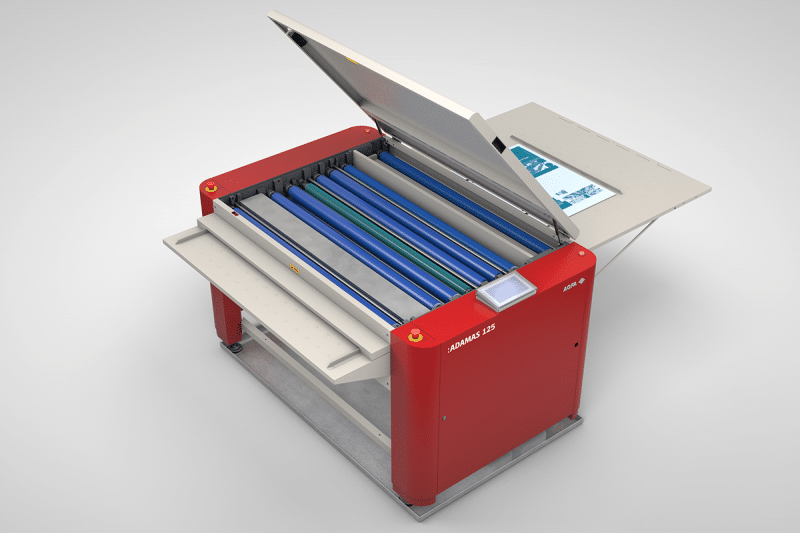

The Adamas COU series consists of dedicated, advanced and compact clean-out units that swiftly finish Adamas plates and take ecology to the next level.

Unlock the Adamas plate’s full potential with the compact Adamas COU85, COU125 and COU 150 clean-out units, based entirely on sustainable innovation that targets ecology, economy and extra convenience (cf. Agfa’s ECO3 approach aiming at the development of cleaner and cost-effective solutions).

Relying on a two-gum concept – dedicated, pH-neutral clean-out gum and protective finishing gum – this clean-out series requires only small quantities of liquids (50 ml/m2) and minimal energy to swiftly clean plates. With a long gum bath life and no water requirement, Adamas COU solutions are showpieces of green technology.

Choose your model: connected online with the plate setter, or stand-alone. There’s no need for a developer or replenisher and everything is pre-set. So once the Adamas clean-out unit is installed, you’re good to go: the unit is designed to handle up to 60,000 m² of plates a year!

Key benefits

- Small ecological footprint: energy-efficient, chemistry-free, no water required to clean the plate

- Two-gum concept: dedicated, pH-neutral clean-out gum and protective finishing gum

- Compact and easy to use for maximum convenience

- Low maintenance clean-out units designed to handle up to 60,000 m² of plates a year

ECO³

Agfa is committed to sustainable innovation that focuses on ecology, economy, and extra convenience—or ECO³. Our hardware, software and consumables make your prepress and printing operations cleaner, more cost-effective and easier to operate and maintain. The ultimate goal? More value for your entire printing business!

Agfa is committed to sustainable innovation that focuses on ecology, economy, and extra convenience—or ECO³. Our hardware, software and consumables make your prepress and printing operations cleaner, more cost-effective and easier to operate and maintain. The ultimate goal? More value for your entire printing business!

Features

- Cascading clean-out technology

- Simplified cleaning

- Operates in daylight, always fully functional

- State-of-the-art intuitive interface

- Extra finishing and drying sections

Technical Specs

| Plate width min/max | 200-850 mm (7.9-33.5”) |

| Plate length min/max | 275 mm (10.9”) |

| Plate thickness | 0.15-0.30 mm (0.006-0.012”) |

| Processing speed | 120-160 cm/min (47-63 inch/min) |

| Power | 2900 W |

| Weight | 280 kg (616 lb) |

| Dimensions | 1424 x 1122 x 1000 mm (56.06 x 44.17 x 39.37) |

| Plate width min/max | 200-1250 mm (7.9-49.2”) |

| Plate length min/max | 275 mm (10.9”) |

| Plate thickness | 0.15-0.40 mm (0.006-0.016”) |

| Processing speed | 120-160 cm/min (47-63 inch/min) |

| Power | 2900 W |

| Weight | 360 kg (792 lb) |

| Dimensions | 1824 x 1122 x 1000 mm (71.81 x 44.17 x 39.37) |

| Plate length min/max | 200-1480 mm (7.9-58.2”) |

| Plate length min/max | 275 mm (10.9”) |

| Plate thickness | 0.15-0.40 mm (0.006-0.016”) |

| Processing speed | 160 cm/min (63 inch/min) |

| Power | 2900 W |

| Weight | 430 kg (946 lb) |

| Dimensions | 2074 x 1122 x 1000 mm (81.65 x 44.17 x 39.37) |