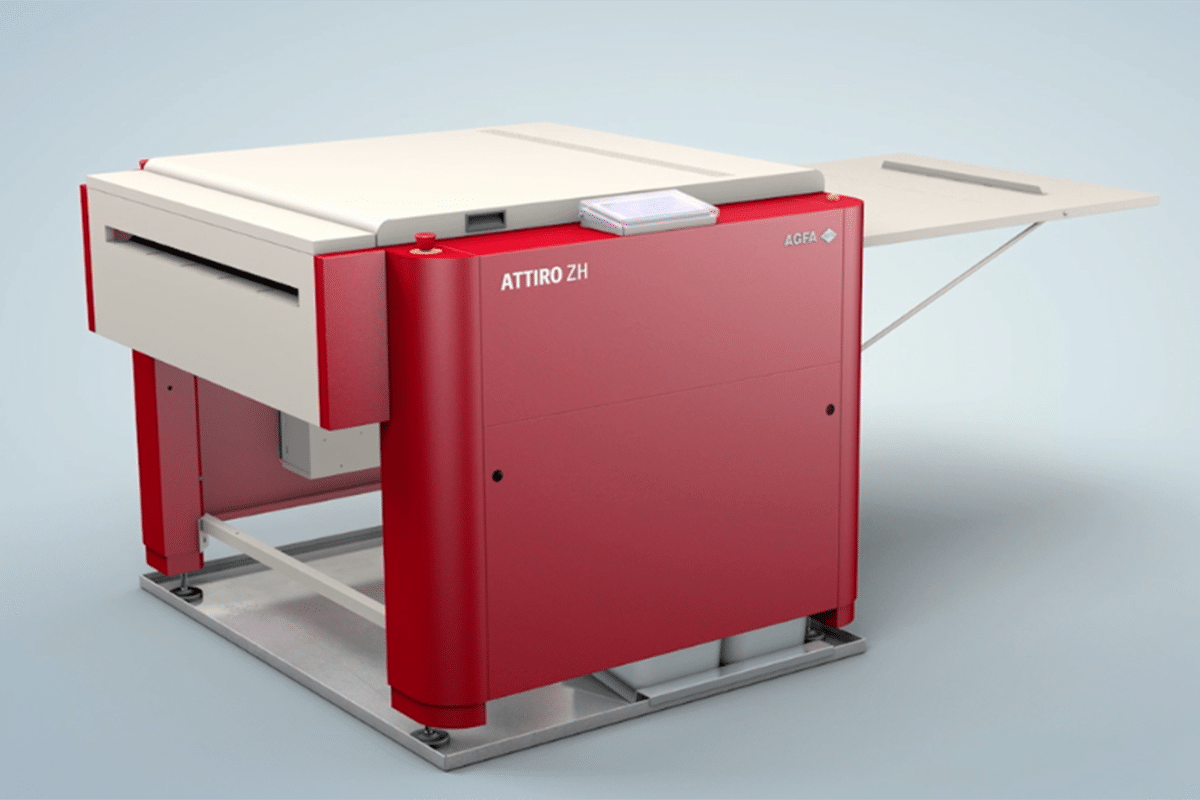

Attiro ZH

Saving money and the planet while cleaning out your violet chemistry-free plates? Use Attiro ZH, a clean-out unit that uses a unique cascade concept and zero heat.

Meet Attiro ZH, the high-speed clean-out unit for your violet chemistry-free plates. Its groundbreaking cascade technology makes your operations both more productive and sustainable, as the concentrated gum is reused in three cascading sections. In this way, the non-imaged areas are effectively removed and there is no risk of oxidizing. The result: minimal gum consumption and little waste for a maximal clean-out effect. Full maintenance, with our dedicated circulation cleaner ATTIRO CareClean, is only required after 8,000 m².

The addition of the Attiro Cleaning Module (ACM) even extends the main cleaning cycle for Attiro COUs to 12,000 m² of plate consumption. Furthermore, the two intermediate cleaning processes at 4,000 and 8,000 m² are executed as part of an automated process that starts with a simple keystroke on the Attiro display and requires no further intervention from the operator.

The Attiro ZH clean-out unit forms a very attractive solution combined with the Avatar V-ZH preheat-free chemistry-free printing plate, and the Advantage N platesetters.

Key benefits

- No preheat unit results in reduced CAPEX, up to 80% energy savings, more floor space, and no buckling of plates because of heating/cooling

- Minimal gum consumption for maximal clean-out effect; less transport of gum bottles

- Extensive bath life, with full maintenance only required after 8,000 m² (or 12,000 m² when the Attiro Cleaning Module is installed)

- Recommended circulation cleaner: ATTIRO CareClean

- Fully flat plate transport through the clean-out unit leaves plates unbent by rollers

- Easy visual check and no mix-ups on press thanks to high-contrast image on the gummed plate

- High speed (up to 400 plates per hour) makes it the perfect match for high production, heavy-duty environments

Watch the movie

ECO³

Agfa is committed to sustainable innovation that focuses on ecology, economy, and extra convenience—or ECO³. Our hardware, software and consumables make your prepress and printing operations cleaner, more cost-effective and easier to operate and maintain.

Agfa is committed to sustainable innovation that focuses on ecology, economy, and extra convenience—or ECO³. Our hardware, software and consumables make your prepress and printing operations cleaner, more cost-effective and easier to operate and maintain.

The ultimate goal? More value for your entire printing business!

Unique cascade concept

Unique cascade concept

CLEANING MODULE

Gum 1: 95 % of all non-imaged areas are removed from the plate.

Gum cascades into the first tank from the second tank and is sprayed on the plate to remove the non-imaged areas. The imaged areas are bound to the substrate and therefore not washed away by the gum. As most of the clean-out happens in this first gum section, it contains most of the cleaned out emulsion. The exhausted gum is drained off.

Gum 2: The remaining non-imaged areas are removed from the plate.

The gum mix from the third tank cascades into the second tank, removes the remaining non-imaged areas, and then cascades into the first tank.

Gum3: A layer of fresh gum is applied to prevent the plate from oxidizing the grained and anodized aluminum.

The final clean-out step is carried out with diluted gum fresh from the bottle, thus ensuring a perfectly clean plate. The fresh gum and water from the tank in the third section then cascade into the tank of the second section.

Dryer section: The plate is dried to enable immediate handling, independent of format.

Hot air is blown through a pair of air tubes, which dries the plate on both sides. As a result, further handling of the plate is immediately possible.

LED curing

A low energy LED bar takes care of final curing of the plate in the drying section.

Technical Specs

Attiro ZH

Performance |

|

| Plate type | Avatar V-ZH preheat-free chemistry-free photopolymer offset plates |

| Plate width, min.-max. | 200-710 mm (7.9-28”) |

| Plate length, min. | 275 mm (10.9”) |

| Plate thickness, min.-max. | 0.15-0.30 mm (0.006-0.012”) |

| Plate speed | 40-300 cm/min |

| Plate volume | Up to 400 plates/hour |

| Brush speed | Gum 1: 200 rpm (fixed) Gum 2: 150 rpm (fixed) |

| Water | Total hardness < 6° dH or Osmosis water Connection: 3/4 gas Max. pressure: 3 bar Drain tube: inner diameter 25 mm |

Mechanical specifications |

|

| Temperatures | Dryer min.-max.: 49-70°C (120-158°F) |

| Tank volumes | Gum 1: 7.5 lit. (1.98 US gal.) Gum 2: 5.5 lit. (1.45 US gal.) Gum 3: 4.5 lit (1.19 US gal.) |

| Noise emission (max.) | < 70 dB |

Physical specifications |

|

| Weight cleaning module incl. crate |

285 kg (628 lb) 385 kg (848 lb) |

| Dimensions cleaning module (w x d x h) incl. crate |

1423 x 1270 x 980-1230 mm (56.0 x 50.0 x 38.6 to 48.4”) 1550 x 1350 x 1220 mm (61.0 x 53.2 x 31.5”) |

Electrical specifications |

|

| Power supply | EUR Single phase: 1W + N + PE 230V / 9.0 Amps, 50/60Hz. USA: Single phase: 2W + PE 208 – 230V / 9.0 Amps, 50/60Hz. |

| Voltage tolerances | +/- 10% |

| Power EUR/US | 2000 Watt hour |

| Heat dissipation | 6824 BTU |

| Energy consumption (under standard working conditions for 1 h) | Ready (Standby): 0.03 kWh Processing: 0.5 kWh Logic off (device switched off via touch panel only, main switch remains on): 0.01 kWh |